THE PROBLEM WITH MODERN ENGINES

The modern engine is an amazing technological marvel. Car manufacturers around the world have been designing engines to be environmentally friendly, very economical and incredibly powerful.

The use of high-tech alloys and computer controlled mechanicals has enabled engine designers to build engines which 20 years ago would have been unheard of.

Today’s engines have amazing new components like variable camshaft control and variable valve openings, just to name a few. All these new systems and devices have quadrupled the amount of internally moving parts inside the engine, particularly the cylinder head. Again, compared to twenty years ago, this is mind boggling!

Strict environmental controls and emissions standards, and consumer demands for better fuel economy and performance have also forced designers to develop direct injection systems for both petrol and diesel engines. These new injection systems now inject fuel directly inside the combustion chamber instead of inside the inlet manifold and port. The advancement in technology has enabled this super-efficient design to now become available.

SO WHAT’S THE PROBLEM?

Now okay, you may think these new high-tech engines are good, and of course they are, but like many things in life, good things always seem to come with a price, or even unintended consequences.

Please excuse me if I now become a bit more technical but I’ll try and keep it to a minimum.

Sometimes technology generates new problems. Take the inlet manifold, for example. Once, there was a carburettor sitting on top of the engine. Air mixed with fuel was delivered above the throttle, which was awash in petrol, one of the world’s great solvents. So carbon could not build up because of the washing action of the swirling, fuel laden air.

Direct injection doesn’t have the fuel mixed with the air, so the natural cleaning action of the petrol can’t occur anymore. So yet again the introduction of new and better systems has by their very design caused an unintended problem.

As a result, it’s common now to find vehicles with very dirty inlet manifolds and throttle bodies caused by carbon build up, bad enough to cause some components to stick and fail. In extreme cases, the blockages can be so bad that the airflow entering the engine becomes restricted. Such an obstruction can result in poor idle, a stalling condition and a drop in performance and fuel economy. Customers complain of a loss of power or poor fuel economy.

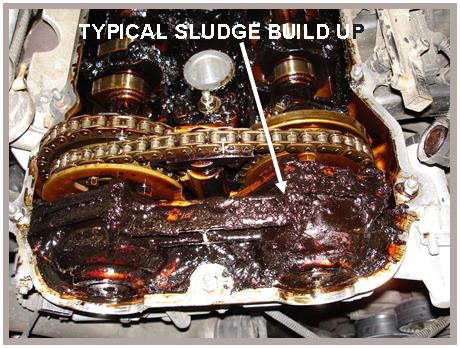

SERIOUS OIL SLUDGE

Another issue modern engines face is one which can be easily preventable. It’s the fact that many, many engines are creating huge amounts of internal sludge.

Our experience has shown that sludge is most likely caused by excessively long oil change intervals. We’ve seen so many “dealer serviced” engines which have enormous amounts of sludge build up.

The intervals that BMW follows under the maintenance program, as well as the intervals indicated by the vehicle’s on-board oil change reminder system, are in our opinion far too long. Additionally, this is compounded by short drive times, as the condensation and acids in the oil do not get hot enough to burn off. Technically, oil sludge is the breakdown product of over-stressed oil in your engine.

SO WHAT’S CAUSING THE SLUDGE?

Oil that is stressed by contaminants and oxidation, or if it has to work longer that it was really designed to, will break down into a gel that sticks to your engine parts. As the gel or sludge sticks, there is less good oil to circulate and do its protective job.

A sludge contaminated engine is being damaged every minute it’s operating. Sludge can also block up oil galleries and pipes, resulting in loss of oil pressure. This lack of oil pressure and flow can cause catastrophic component failures like worn timing chains and bearing failures. These failures are things we see first-hand on many occasions.

ENGINES BEGIN TO BURN AND USE OIL

Sludge build up, as well as carbon build up can also cause engines to use or rather burn oil, resulting in annoying and costly oil top ups as well as blowing smoke from the exhaust. The combination of carbon build up and sludge around the piston rings creates a situation where the oil control rings can’t scrape the oil off the bores during the piston’s downward stroke. Normally, the oil would flow from the rings and then through the small drain holes behind where the rings sit. If the drain holes are blocked then the oil remains on the surface of the bore and consequently gets burnt during the power stroke in the cylinder.

WHAT CAN BE DONE ABOUT IT?

Now I have good news! As you know, the advent of cutting-edge technology has given rise to the development of amazing new engine designs and injection systems. At the same time, cutting-edge technology has also enabled chemical engineers to design incredible new additives which remove and dissolve carbon deposits and sludge build up.

Now before you start baulking at the word additives, things are different nowadays. Years ago, many shonky companies were exposed for selling additives which did nothing like they claimed. Of course this gave the motor industry a bad name and fortunately, additives became a thing of the past. These days, additives actually work and some are even endorsed by manufacturers to fix minor and in some cases, major issues, especially transmissions which can develop harsh shifting.

ADDITIVES ARE BACK!

The good news is there are now some fantastic products out there to combat excessive carbon and sludge build up. We’ve been using these additives and chemicals for some time now with great success. Many customers have been delighted with the results, especially on the oil burning engines, which the use of additives reduced oil consumption and restored performance.

Below are the types of additives available and their applications:

OIL PRE-FLUSH:

This is added to the engine oil 15 minutes prior to changing the old oil. This removes excessive sludge from piston rings and oil galleries. Reduces oil consumption and restores performance and reliability. Engine smoke is also reduced or eliminated. Costs $33.00

FUEL TREATMENT:

Added to fuel tank. This chemical removes carbon deposits around intake valves and cleans fuel injector nozzles. Ongoing use like every three months is good to maintain a clean system. This additive costs $38.50 per serve.

FUEL TREATMENT INTENSIVE CLEAN:

Commonly called Carbon Clean. There are two versions: one for old engines and one for new engines. A Machine apparatus is required to connect to the fuel system where a chemical is mixed with the petrol or air and then the engine runs on this solution for about one hour. This is similar to the tank additive except that it is extremely powerful. This chemical removes carbon deposits around intake ports and valves. Cleans and unblocks fuel injector nozzles.

This should be performed every 30,000 kms on modern engines and every 40,000 kms on older technology engines. This costs $175 for a Carbon Clean on petrol engines and $275 to $295 on diesel engines.

So there you have it, modern engines are good but they can have their pitfalls. Fortunately we now have exciting and relatively low-cost solutions to keep these amazing, high-tech engines in tip-top running condition.